Interlake Mecalux Gravity Flow pallet racking

• Interlake Carton Flow pallet racking

• Interlake Mecalux Pallet Flow pallet racking

• Interlake Push Back pallet racking

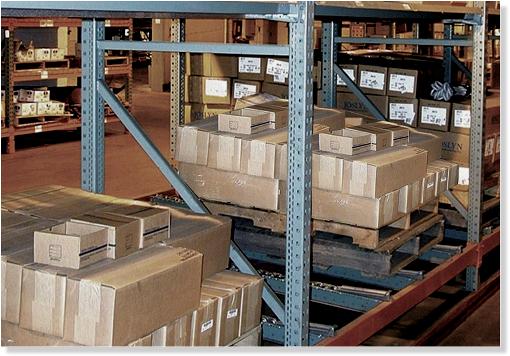

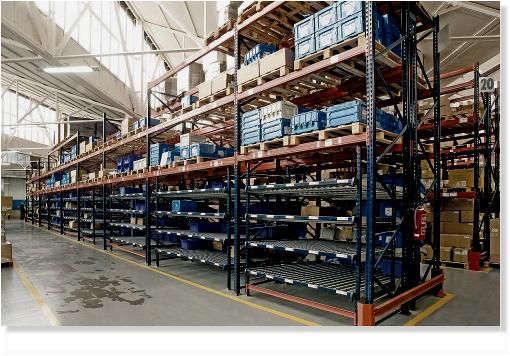

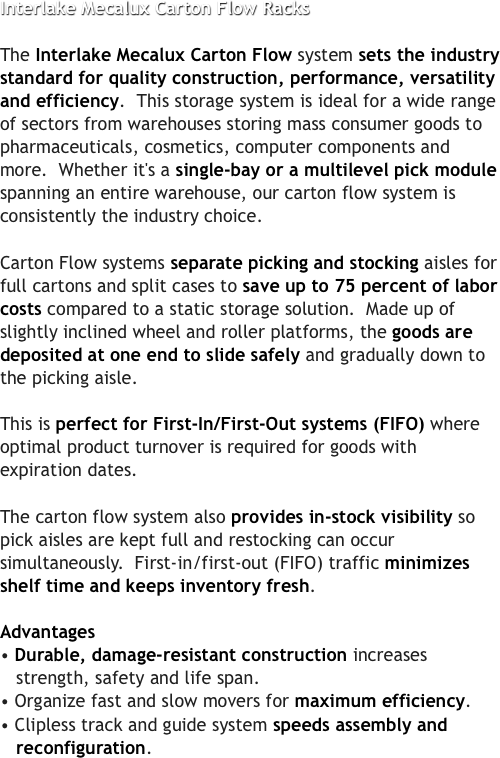

Interlake Mecalux Carton Flow pallet racking

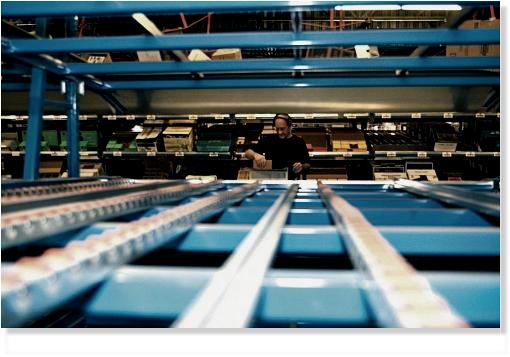

The Interlake Mecalux Carton Flow pallet rackingsystem sets the industry standard for quality construction, performance, versatility and efficiency. This storage system is ideal for a wide range of sectors from warehouses storing mass consumer goods to pharmaceuticals, cosmetics, computer components and more. Whether it's a single-bay or a multilevel pick module spanning an entire warehouse, our carton flow system is consistently the industry choice.

Interlake Carton Flow pallet racking systems separate picking and stocking aisles for full cartons and split cases to save up to 75 percent of labor costs compared to a static storage solution. Made up of slightly inclined wheel and roller platforms, the goods are deposited at one end to slide safely and gradually down to the picking aisle.

This is perfect for First-In/First-Out systems (FIFO) where optimal product turnover is required for goods with expiration dates.

The Interlake Mecalux carton flow system also provides in-stock visibility so pick aisles are kept full and restocking can occur simultaneously. First-in/first-out (FIFO) traffic minimizes shelf time and keeps inventory fresh.

Advantages

• Durable, damage-resistant construction increases strength, safety and life span.

• Organize fast and slow movers for maximum efficiency.

• Clipless track and guide system speeds assembly and reconfiguration.

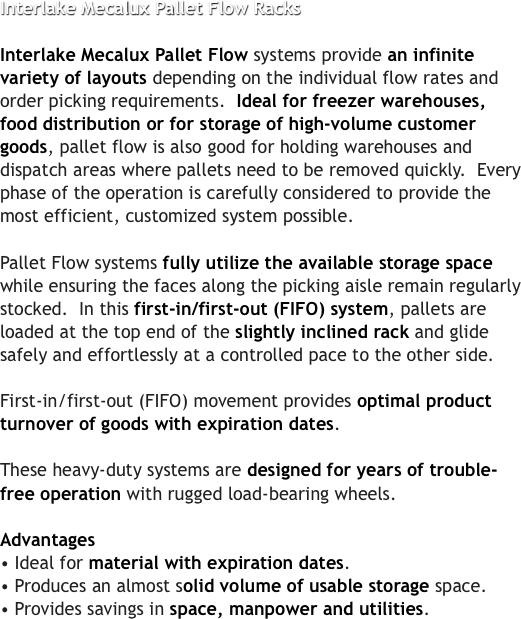

Interlake Pallet Flow pallet racking

Interlake Pallet Flow pallet racking systems provide an infinite variety of layouts depending on the individual flow rates and order picking requirements. Ideal for freezer warehouses, food distribution or for storage of high-volume customer goods, pallet flow is also good for holding warehouses and dispatch areas where pallets need to be removed quickly. Every phase of the operation is carefully considered to provide the most efficient, customized system possible.

Interlake Mecalux Pallet Flow systems fully utilize the available storage space while ensuring the faces along the picking aisle remain regularly stocked. In this first-in/first-out (FIFO) system, pallets are loaded at the top end of the slightly inclined rack and glide safely and effortlessly at a controlled pace to the other side.

First-in/first-out (FIFO) movement provides optimal product turnover of goods with expiration dates.

These heavy-duty systems are designed for years of trouble-free operation with rugged load-bearing wheels.

Advantages

• Ideal for material with expiration dates.

• Produces an almost solid volume of usable storage space.

• Provides savings in space, manpower and utilities.

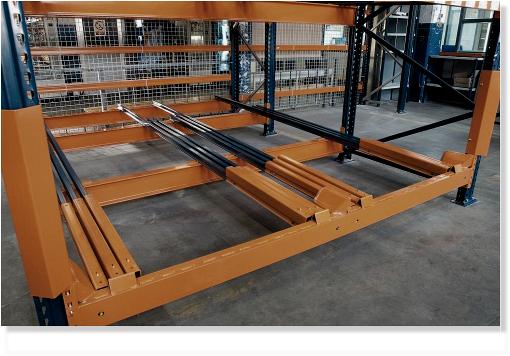

Interlake Push Back Pallet Racking Systems

Interlake Push Back Pallet Racking is designed for high-density, multiple-product storage situations, combining excellent selectivity and a maintenance-free design. This versatile system uses nesting carriages to store pallets up to five deep, providing multiple pick facing with extremely high throughput.

Each level can store a different reference. Loading and unloading is done using the same aisle (LIFO system).

Up to 4 pallets per level can be stored.

As each pallet is loaded, it's placed on a free-rolling carriage that is pushed back into the system by loading additional pallets. When unloading, gravity moves the pallets forward to the aisle on the telescoping carriages, eliminating the need for reaching or driving into the rack.

Interlake Mecalux Push Back Pallet Racking provides a wide variety of options and configurations to ensure the optimal design for any application. The structural cart construction maintains cleanliness and the debris-free design is perfect for food applications. Available in two-, three-, four-, and five-deep pallet designs with multiple accessory options, Push-Back Rack provides unparalleled versatility.

Advantages

• Allows efficient use of space with limited sacrifice in product accessibility.

• Provides the optimal combination of selectivity and storage density.

• Sturdy construction affords years of maintenance free operation.